EDIH4Marche, in collaboration with i-Labs Industry, carried out an ambitious automation and innovation project for Altesia, a Marche-based SME specializing in implementing solutions for Food companies. This project, published among the success stories by the European Digital Innovation Hubs network, focused on a feasibility study for a collaborative robotic palletization system aimed at optimizing efficiency, safety, and product quality in end-of-line operations.

An Added Value: EDIH4Marche’s Test Before Invest Service

Altesia benefited from the Test Before Invest service offered by EDIH4Marche, a crucial initiative designed to help companies evaluate and experiment with innovative technologies before making a full investment. This service allows businesses to reduce investment risks by offering a preliminary testing phase in controlled environments, such as the i-Labs Industry laboratories. For Altesia, the Test Before Invest phase was essential for optimizing technology choices and designing a tailored automation system, verifying every aspect in advance to ensure the system met specific production needs.

Challenges Addressed

The project’s objective was to assess the feasibility of automating the end-of-line palletization process while meeting stringent requirements. Among the primary challenges, it was necessary to develop a system that could:

- Support two palletization modes (tight and wide sequence);

- Palletize four pallets simultaneously;

- Handle boxes of various sizes and weights;

- Operate in a limited space while maintaining a high production cycle (400 boxes/hour);

- Use collaborative robots to eliminate the need for safety barriers.

Technological Solutions Implemented

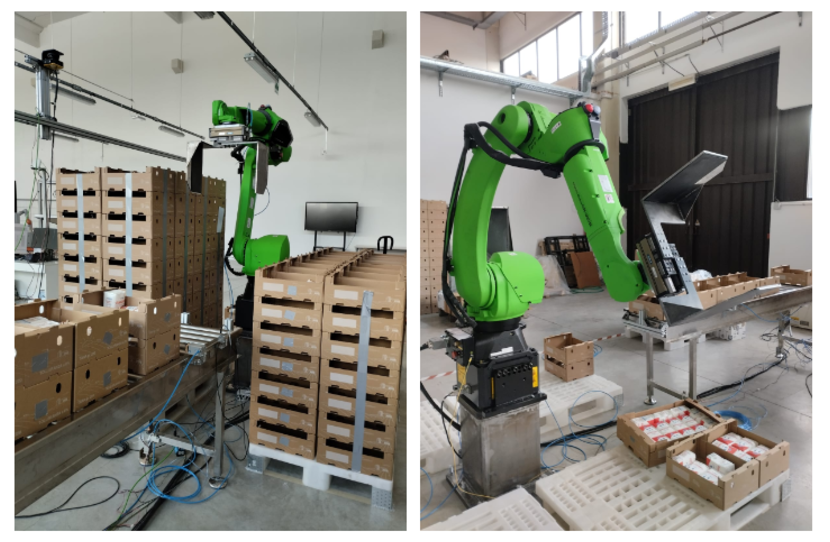

To meet these requirements, the FANUC CR-35iB collaborative robot was selected, equipped with a Schunk PHL-40 pneumatic gripper, specifically designed to handle boxes without damaging them. The gripper uses rubber layers to increase grip strength without compromising box integrity. Simulations conducted with Roboguide software demonstrated that the robot could palletize up to 480 boxes per hour, exceeding manual handling capabilities.

Tests conducted at the i-Labs Industry laboratories confirmed the solution’s effectiveness, showing that the robotic system could operate efficiently within space constraints and with the flexibility needed to adapt to future production requirements.

Results and Benefits for Altesia

The implemented solution delivered significant advantages for Altesia:

- Increased Efficiency and Productivity: With a capacity of 480 boxes per hour, the system reduces bottlenecks and improves productivity, enabling Altesia to respond more quickly to market demand.

- Labor Cost Reduction: Automation frees workers from repetitive tasks, allowing them to focus on higher-value activities such as quality control and process optimization.

- Enhanced Safety: Collaborative robotics reduce the need for manual lifting of heavy loads, minimizing injury risks and creating a safer work environment.

- Guaranteed Product Quality: The advanced gripper ensures delicate handling, minimizing product damage during the palletization process.

- Flexibility and Scalability: The robotic system is designed to adapt to future configuration changes, providing Altesia with a competitive edge and the ability to efficiently expand its production capacity.

Social and Economic Impact

The introduction of a robotic palletization system provides significant social and economic benefits:

- Increased Competitiveness: Automation positions Altesia as a leader in the sector, improving its competitiveness and potentially attracting new clients.

- Process Optimization: Robotic palletizers accelerate operations, reducing downtime and optimizing workflows by operating without interruptions.

- Operational Cost Savings: The robotic system reduces the need for labor in physically demanding tasks, lowering labor costs and increasing profitability.

Opportunities for Marche-Based SMEs

The solution developed with Altesia demonstrates that robotic automation is a valid choice for companies looking to improve efficiency, safety, and quality. EDIH4Marche and i-Labs Industry will continue supporting local SMEs in their digital transformation journey, offering innovative technologies to enhance competitiveness and sustainability.

Special Acknowledgments

EDIH4Marche extends heartfelt thanks to Fabrizio Stella, CEO of Altesia, for his invaluable trust, collaboration, and vision throughout the project. His dedication to innovation and commitment to embracing cutting-edge solutions were pivotal to the success of this initiative.

We also express our gratitude to the teams at i-Labs Industry and the European Digital Innovation Hubs network for their unwavering support and expertise in making this ambitious project a reality.

This collaboration exemplifies the power of partnership and shared innovation, showcasing how collective effort can drive meaningful transformation in the industrial sector.